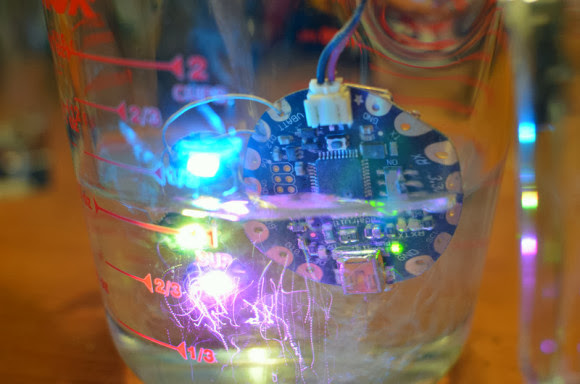

[Abhimanyu Kumar] was watching YouTube videos one day when he came across something called a Polariscope — After learning how it worked, he discovered you can make your own using household items!

First off, what is a Polariscope? Well, put simply, it is a device that can show you the photoelasticity of a clear specimen, which can reveal the stress distribution in the material! And it is actually really easy to make one.

All you need to build your own is:

First off, what is a Polariscope? Well, put simply, it is a device that can show you the photoelasticity of a clear specimen, which can reveal the stress distribution in the material! And it is actually really easy to make one.

All you need to build your own is:

- A polarized light source (any modern LCD monitor)

- A transparent specimen (plastic cutlery, glass statues, plastic you can bend, etc)

- A circular polarizing filter (the cheap 3D glasses you didn’t return at the theater)